В реальном процессе эксплуатации условия отличаются, то есть из-за различных условий работы соответствующие параметры, необходимые для соответствующей обводненности, также различны. Это также затрудняет сборку оборудования для гидроабразивной резки, будь то рабочая платформа с ЧПУ или система высокого давления, она должна соответствовать окружающей среде-

станок для гидроабразивной резки.

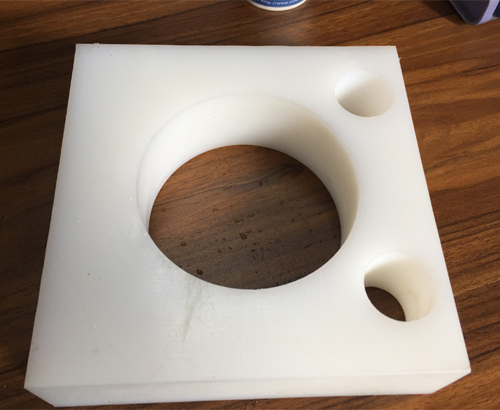

Прежде всего, рабочая платформа с числовым программным управлением для оборудования для резки воды, в этом отношении существует два варианта: одна рабочая платформа с числовым программным управлением консольного типа, а другая - рабочая платформа с числовым программным управлением портального типа, каждая из которых имеет свои характеристики. Механизм движения первого и режущая платформа разделены и не влияют друг на друга; последнее как раз наоборот.

Следовательно, в реальном процессе выбора это зависит от размера материала, который должен быть разрезан устройством для резки водой. Режущая платформа с ЧПУ консольного типа больше подходит для случая, когда размер материала нерегулярен, а режим загрузки и выгрузки не фиксирован.

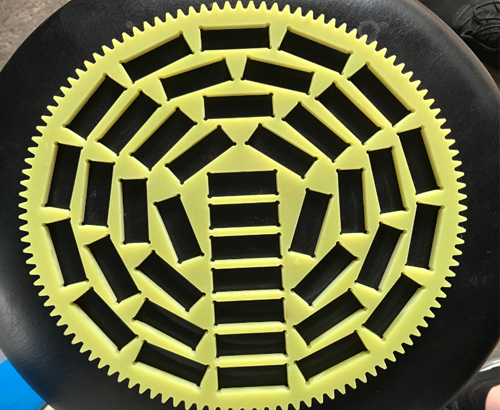

Во-вторых, система высокого давления оборудования для гидроабразивной резки с ЧПУ, этот аспект также тесно связан с материалом, подлежащим резке. Разнообразие, толщина, качество поверхности резания и требования к скорости резания материала будут определять, какое оборудование для резки должно быть сконфигурировано. Система высокого давления-

Китай водоструйный камень для резки.

Например, если это высоковольтная система с напряжением 300 МПа, ее можно использовать для резки твердых материалов толщиной менее 30 мм. Однако, если материал относительно твердый, необходимо использовать систему высокого давления 380 МПа. Он имеет преимущества с точки зрения способности резки, качества поверхности резки, скорости резки и тому подобного.

Кроме того, другие дополнительные элементы для оборудования для резки водой, такие как обработка мягкой воды, автоматическая система подачи песка и т. Д., Одинаково важны для эффекта резки оборудования для резки водой и не могут быть проигнорированы.

Shandong EAAK Machinery Co., Ltd